What is corten steel tube?

Definition and characteristics of corten steel tube

Corten steel tube is primarily composed of iron, carbon, manganese, phosphorus, sulfur, silicon, chromium, and copper. The amalgamation of these elements imparts corten steel tube with its distinctive properties. One of the key characteristics of this remarkable material is its capacity to develop a protective rust-like coating when exposed to the weather, thereby safeguarding the underlying material from corrosion. This self-protecting attribute endows corten steel tube with exceptional durability and resistance to atmospheric corrosion.

Applications and uses of corten steel tube

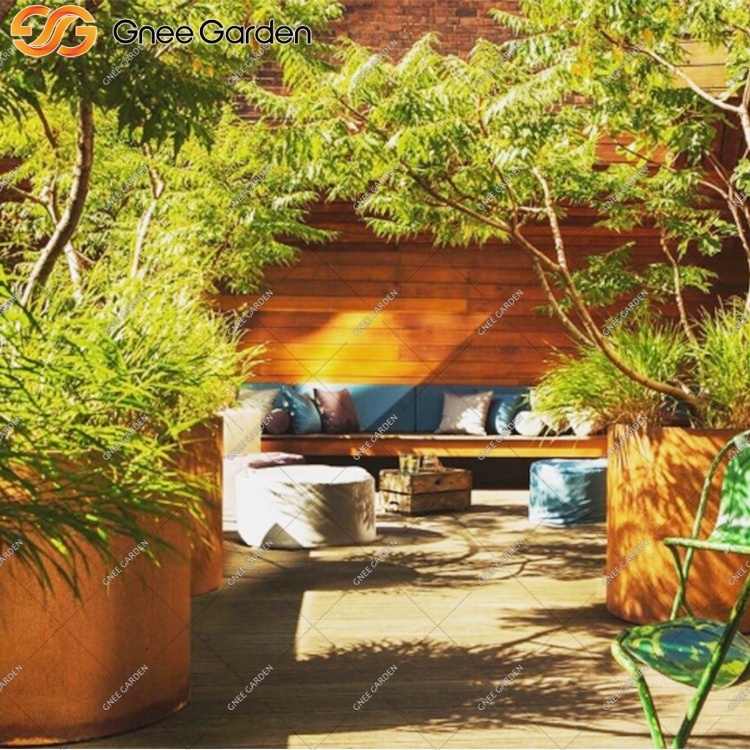

Corten steel tube finds common employment in a multitude of applications across various industries. Its extraordinary weathering ability and aesthetic allure make it a sought-after choice for architectural projects, such as the embellishment of building facades, the construction of bridges, and the creation of outdoor sculptures. Furthermore, corten steel tube is employed in the fabrication of railway wagons, containers, and in the noble pursuit of shipbuilding. Additionally, it can be employed in the realm of landscaping and garden design, as well as for industrial purposes, including the construction of storage tanks and pipelines.

Advantages and benefits of corten steel tube

Corten steel tube bestows upon its users several advantages and benefits when compared to traditional steel materials. Firstly, its ability to form a protective rust-like coating eliminates the need for constant painting and regular maintenance, thereby resulting in considerable cost savings and a reduced environmental impact. Secondly, corten steel tube exhibits high tensile strength and unparalleled corrosion resistance, rendering it an ideal choice for outdoor and structural applications. Additionally, its exceptional weathering ability imparts corten steel tube with a distinctive appearance, thereby augmenting the aesthetic value of architectural designs. Lastly, corten steel tube is readily available and can be effortlessly fabricated and welded, thus providing versatility in design and construction.

How is corten steel tube made?

It involves a series of precise steps that imbue the material with its unique properties and characteristics. The journey begins with the careful selection of only the finest quality steel materials. These chosen materials are then expertly cut into desired lengths and shapes, a task requiring the utmost skill and precision. Once shaped, the steel is subjected to intense heat, causing it to yield and transform into tubes using specialized machinery. This meticulous process ensures that the resulting tubes possess precise dimensions and a flawlessly smooth surface finish. But the journey does not end there. The tubes then undergo a treatment known as weathering, wherein they are exposed to the elements. It is through this exposure that a protective layer of rust develops, not only enhancing the aesthetic allure of corten steel tubes but also providing an impervious barrier against the ravages of corrosion. Thus, these tubes stand as paragons of durability, suitable for a myriad of applications.

Factors influencing the quality of corten steel tube

When considering the quality of corten steel tubes, one must take into account various factors that can exert influence. Among these, the quality of the base steel used in the manufacturing process emerges as a crucial consideration. It is of utmost importance that the steel possess specific chemical compositions and mechanical properties, as this ensures the overall strength and durability of the tubes. Equally significant is the manner in which the manufacturing process is executed. Precise cutting, rolling, and shaping techniques, accompanied by proper heat treatment, all contribute to the dimensional accuracy, surface finish, and structural integrity of the tubes. Additionally, the weathering process, responsible for the development of the characteristic rust layer, must be carefully controlled to achieve the desired aesthetic appeal and corrosion resistance. Only through the meticulous attention to these factors can the highest quality corten steel tubes be achieved.

Comparison with other types of steel tubes

When one undertakes a comparison between corten steel tubes and their counterparts, a multitude of factors come into play. Perhaps the most noteworthy advantage possessed by corten steel tubes is their unparalleled weather resistance. The natural barrier against corrosion provided by the protective rust layer renders them eminently suitable for outdoor applications and environments beset by the harshest of weather conditions. Furthermore, corten steel tubes possess a distinct appearance, characterized by a resplendent, earthy tone and a textured surface. This sets them apart from conventional steel tubes, endowing them with a singular allure. Moreover, these tubes exhibit exceptional strength and durability, making them the epitome of excellence for structural applications where a high load-bearing capacity is an imperative. However, one must not neglect to consider factors such as cost, availability, and the specific requirements of the intended application when faced with the choice between corten steel tubes and other types of steel tubes. A discerning eye and a judicious evaluation are necessary to make the most informed decision.

Maintenance and Care for Corten Steel Tube

The durability and unique weathering properties of corten steel tube are well-known. However, like all materials, it requires regular maintenance and care to prevent corrosion and ensure its longevity. Allow me to impart some essential tips and techniques to assist you in maintaining and protecting your cherished corten steel tube.

Tips for Preventing Corrosion on Corten Steel Tube

To prevent corrosion on your corten steel tube, it is of utmost importance to keep it clean and dry. Regularly inspect the surface for any signs of moisture or dirt buildup, as these can hasten the corrosion process. Avoid placing objects upon the tube that may trap moisture or cause scratches, for these can create localized corrosion spots. Additionally, ensure proper drainage around the tube to prevent the accumulation of water. The application of a protective coating or treatment can also prove advantageous in preventing corrosion.

Cleaning and Maintenance Techniques for Corten Steel Tube

When tending to the cleanliness of your corten steel tube, eschew the usage of harsh chemicals or abrasive cleaning agents, as these may inflict damage upon the protective layer and promote corrosion. Instead, employ a mild soap or detergent mixed with water to gently cleanse the surface. A soft-bristle brush or sponge may be utilized to eradicate dirt or stains. Following the cleansing process, rinse the tube thoroughly with clean water and delicately pat it dry with a soft cloth. Regularly inspect the tube for any signs of damage or rust, and address them promptly to prevent further corrosion.

Protective Coatings and Treatments for Corten Steel Tube

Applying a protective coating or treatment to your corten steel tube can significantly enhance its resistance to corrosion. An array of options exists, including clear sealants, rust converters, and weathering accelerators. Clear sealants create a protective barrier that thwarts the infiltration of moisture and oxygen upon the surface, while rust converters chemically transform rust into a stable compound. Weathering accelerators may be employed to expedite the natural weathering process, imparting a more uniform and aesthetically pleasing appearance to the tube.

Frequently Asked Questions About Corten Steel Tube

Here are the most common queries and concerns regarding corten steel tube:

1. What is corten steel tube?

Corten steel tube is a type of steel alloy that acquires a protective layer of rust when exposed to atmospheric conditions.

2. What are the benefits of employing corten steel tube?

Corten steel tube offers unyielding strength and durability, superb resistance to atmospheric corrosion, minimal maintenance requirements, aesthetic appeal, and a wide range of applications.

3. Can corten steel tube be subjected to welding?

Yes, corten steel tube can be welded using appropriate techniques and consumables to preserve the protective rust layer.

4. How long does it take for corten steel tube to develop its characteristic rust patina?

The duration for the formation of the rust patina can vary, but it generally takes several months. Exposure to moisture and air can expedite the process.

5. Is corten steel tube suitable for outdoor applications?

Yes, corten steel tube is suitable for outdoor applications due to its exceptional resistance to corrosion. It is commonly used in architectural structures, landscaping, and construction projects.

6. How can corten steel tube be maintained?

Corten steel tube requires minimal maintenance. Regular cleaning with water and mild detergent can remove dirt and debris. The protective rust layer eliminates the need for painting or coating.

7. Can corten steel tube be used in marine environments?

Yes, corten steel tube can be used in marine environments. Regular maintenance and proper design considerations are necessary for long-term durability.

8. Can corten steel tube be painted or coated?

While corten steel tube is often left unpainted to showcase its natural appearance, it can be painted or coated. However, this alters the unique aesthetic and eliminates the development of the protective rust layer.

9. Are there any limitations to using corten steel tube?

Some limitations of corten steel tube include higher initial cost, potential staining of adjacent materials during the initial rusting process, and unsuitability for water bodies with high chloride content.