Advantages of Custom Welded Perforated Corten Steel

The many advantages of custom welded perforated corten steel have made it an exceedingly popular choice in a variety of applications. Its durability and longevity are greatly increased, making it an ideal material for numerous projects. Furthermore, its aesthetic appeal is greatly enhanced, adding to its desirability.

One of the most notable benefits of custom welded perforated corten steel is its exceptional resistance to corrosion. Structures constructed from this remarkable material can withstand even the harshest weather conditions, ensuring their integrity remains intact over time. This superior corrosion resistance sets it apart from other materials, making it a preferred choice for those seeking long-lasting and reliable solutions.

Moreover, the versatility of custom welded perforated corten steel allows it to be utilized in a wide range of applications. From grand architectural designs to intricate landscaping projects, this adaptable material can be shaped and molded to suit any desired outcome. Its flexibility and strength make it an excellent choice for those seeking a material that can be customized to meet their specific needs.

With its numerous advantages, custom welded perforated corten steel is a material that combines both practicality and beauty. Its ability to withstand the test of time, coupled with its aesthetic appeal, makes it a favored choice among architects, designers, and builders alike. Whether it is used to construct a magnificent building or to create an enchanting garden feature, corten steel proves to be a reliable and visually pleasing option.

Applications of Custom Welded Perforated Corten Steel

Custom welded perforated corten steel finds a wide range of applications due to its unique properties and aesthetic appeal. This versatile material is used in various industries and sectors, including architecture, landscaping, interior design, and industrial applications.

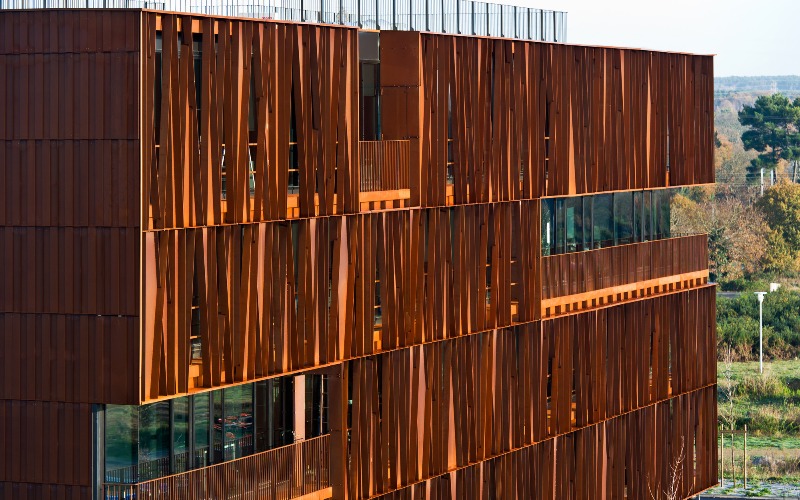

Architectural and Building Facades

The use of custom welded perforated corten steel is highly esteemed in architectural projects for its distinctive weathered appearance and enduring strength. It is frequently employed in building facades to create a modern and industrial aesthetic. The intricate patterns created by the perforations add an element of visual interest, allowing for creative designs and captivating interplays of light. As time passes, a rust-like patina develops, further enhancing the overall allure of the structure.

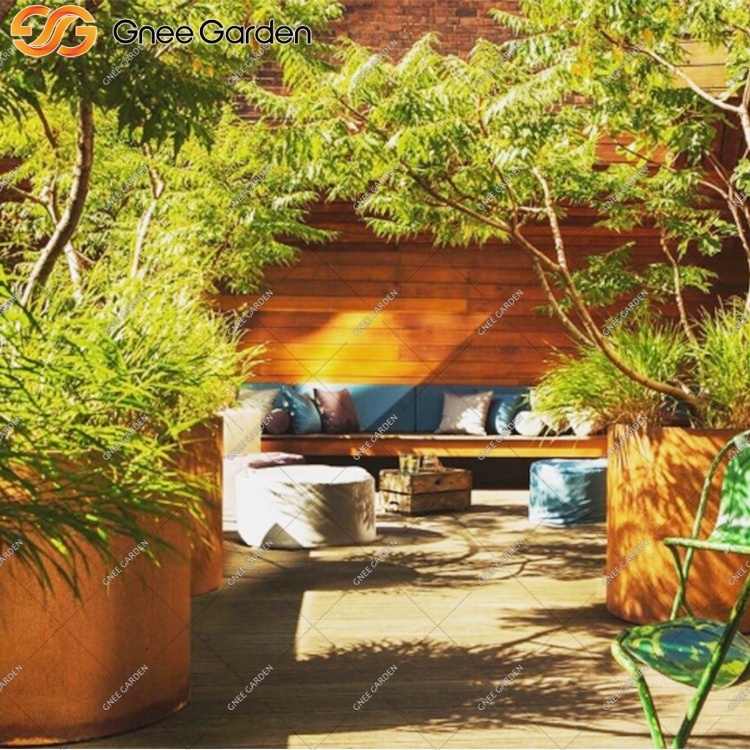

Landscaping and Outdoor Structures

Within the realm of landscaping, custom welded perforated corten steel is sought after for its ability to harmonize seamlessly with the natural surroundings. It is commonly utilized for garden planters, retaining walls, fences, and screens. The presence of perforations not only imparts a decorative touch but also ensures proper drainage and airflow. The inherent resistance of corten steel to corrosion renders it an ideal choice for outdoor structures that are exposed to diverse weather conditions.

Interior Design and Decorative Elements

Corten steel is increasingly being incorporated into interior design to introduce an element of industrial elegance. It can be employed for various decorative elements, such as wall panels, room dividers, and furniture. The intricate patterns created by the perforations generate captivating visual effects, allowing light and shadows to dance upon the surfaces. The warm and earthy tones of corten steel bestow a rustic charm upon interior spaces.

Industrial and Commercial Applications

Custom welded perforated corten steel is widely utilized in industrial and commercial settings. Its durability, strength, and resistance to corrosion render it suitable for a plethora of applications. It is commonly employed in the manufacturing of equipment, storage containers, bridges, and infrastructure projects. Moreover, the perforated design can serve functional purposes, such as ventilation or filtration systems, in these industrial and commercial contexts.

Maintenance and Care Tips for Custom Welded Perforated Corten Steel

Custom welded perforated corten steel, a material both durable and visually captivating, finds common use in architectural and landscaping projects. To ensure its longevity and preserve its aesthetic appeal, regular maintenance and care are essential. By adhering to the following tips, you can keep your corten steel in optimal condition:

Regular Cleaning and Removal of Debris

To prevent the accumulation of dirt, dust, and organic matter, it is of utmost importance to regularly cleanse your custom welded perforated corten steel. Gently cleanse the surface with mild soap and water, employing a soft brush or sponge. Refrain from employing abrasive cleaners or tools that may mar or harm the steel. In addition, eliminate any debris, leaves, or other objects that may collect within the perforations, as they can trap moisture and contribute to corrosion.

Application of Protective Coatings or Sealants

Application of protective coatings or sealants can aid in augmenting the longevity of your corten steel and safeguarding it from the elements. Numerous options exist, including clear coatings that uphold the steel’s natural appearance or tinted coatings that introduce a desired hue. Prior to application, ensure the surface is pristine and dry. Adhere to the manufacturer’s instructions for proper application and reapplication intervals.

Monitoring and Addressing Any Signs of Corrosion

Though corten steel is renowned for its weathering properties, it remains susceptible to corrosion under certain circumstances. Regularly inspect the steel for any indications of corrosion, such as orange or brown discoloration, rust stains, or pitting. Should any corrosion be detected, address it promptly to prevent further harm. Employ a wire brush or sandpaper to eliminate the affected area, and contemplate applying a rust converter or inhibitor to deter future corrosion.

Professional Inspection and Maintenance Schedule

Enlisting the services of a professional for periodic inspections and maintenance can aid in identifying and addressing any issues before they escalate. Consider scheduling regular inspections to evaluate the condition of your custom welded perforated corten steel and receive expert recommendations on maintenance and repairs. A professional can also provide guidance on specific care requirements based on the location and environmental factors influencing your corten steel.

Frequently Asked Questions

What are the advantages of custom welded perforated corten steel?

Custom welded perforated corten steel offers exceptional resistance to corrosion, making it durable and long-lasting. It also has aesthetic appeal and can be shaped and molded to suit any desired outcome.

What are the customization options for perforated corten steel?

Perforated corten steel offers a variety of customization options, including different shapes, dimensions, finishes, textures, and the incorporation of personalized designs and logos.

What are the applications of custom welded perforated corten steel?

Custom welded perforated corten steel is used in architecture, landscaping, interior design, and industrial applications. It is commonly used in building facades, garden planters, interior decorative elements, and industrial equipment.

What factors should be considered when selecting a supplier of custom welded perforated corten steel?

Important factors to consider when selecting a supplier include their experience and expertise in welding and fabrication, the quality of materials and workmanship, timely delivery and installation services, and customer reviews and testimonials.

What maintenance and care tips should be followed for custom welded perforated corten steel?

Tips for maintaining corten steel include regular cleaning and removal of debris, application of protective coatings or sealants, monitoring and addressing any signs of corrosion, and scheduling professional inspections and maintenance.