Choosing the Right Welding Wire for Corten Steel

When it comes to welding Corten steel, choosing the right welding wire is crucial to ensure a strong and durable weld. Corten steel, also known as weathering steel, requires low-alloy welding wires with specific characteristics and benefits. By selecting the right welding wire, you can achieve successful welding processes and high-quality welds when working with Corten steel.

Using low-alloy welding wires for welding Corten steel offers a range of benefits, including corrosion resistance, strength, durability, and compatibility with the material’s composition. Additionally, following safety precautions and best practices is essential to ensure a safe and successful welding process when working with Corten steel.

-

Key Points

Key Points:

- – Low-alloy welding wires are essential for welding Corten steel.

- – Characteristics of low-alloy welding wires include high tensile strength and corrosion resistance.

- – Tips for selecting the right welding wire for Corten steel.

- – Safety precautions and best practices for welding Corten steel.

Selecting the Right Welding Wire for Corten Steel

with regards to welding Corten metallic, choosing the proper welding cord is crucial to make sure a robust and durable weld. Corten steel, additionally called weathering metallic, is a set of steel alloys that shape a stable rust-like appearance after numerous years of publicity to climate. To weld Corten steel correctly, low-alloy welding wires are typically used due to their precise traits and advantages.

Low-Alloy Welding Wires characteristics:

| characteristics | blessings |

|---|---|

| high tensile power | presents strong welds |

| right ductility | Reduces the threat of cracking |

| Corrosion resistance | facilitates preserve the integrity of the weld in outside environments |

hints for selecting the proper Welding twine:

- select a low-alloy welding cord with a tensile power that matches or exceeds that of Corten metal

- opt for welding wires with suitable ductility to save you cracking throughout welding

- select wires with corrosion resistance residences for lengthy-lasting welds

with the aid of choosing the proper welding wire with the appropriate traits, you may ensure a a hit welding manner and achieve extraordinary welds when working with Corten metallic.

Characteristics and Benefits of Using Low-Alloy Welding Wires

with regards to welding Corten steel, the use of low-alloy welding wires is vital for accomplishing finest effects. Those wires are in particular designed to work nicely with Corten metal, supplying numerous key advantages:

1. Corrosion Resistance: Low-alloy welding wires help keep the corrosion-resistant residences of Corten steel, ensuring that the welded joints have the equal stage of protection against rust and corrosion.

2. Power and durability: by using the use of low-alloy welding wires, you may ensure that the welded joints are sturdy and sturdy, capable of withstanding harsh environmental conditions with out compromising the structural integrity of the Corten metallic.

3. Compatibility: Low-alloy welding wires are specially formulated to be compatible with Corten metal, making sure a clean and green welding procedure without any troubles or complications.

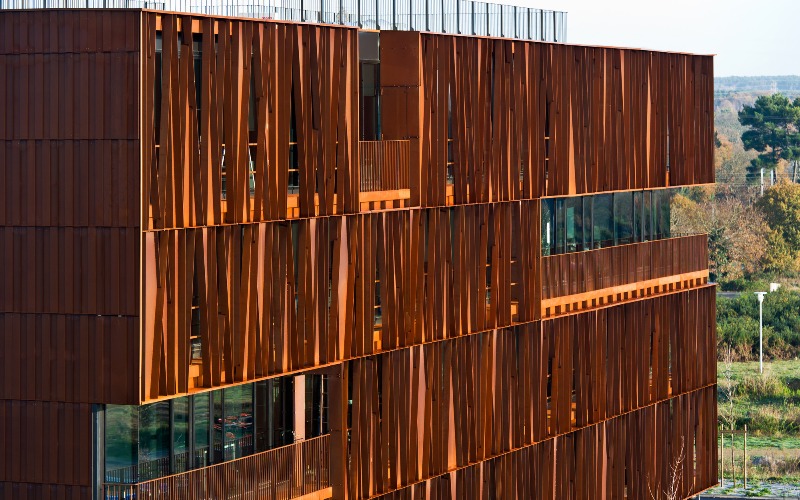

4. Aesthetic attraction: Welding Corten metal with low-alloy welding wires helps hold the distinct rust-like look of the material, making sure a continuing and visually appealing end.

usual, the usage of low-alloy welding wires for welding Corten steel offers a range of blessings that make contributions to the overall excellent and sturdiness of the welded joints. It’s miles vital to pick the right type of welding twine primarily based on the precise requirements of the task to make certain the best outcomes.

Tips for Welding Corten Steel Effectively

with regards to welding Corten metallic, choosing the right welding twine is essential for accomplishing robust and sturdy welds. Low-alloy welding wires are generally used for welding Corten metal because of their compatibility with the cloth’s composition. Here are some hints to help you weld Corten metal correctly:

| Tip | Description |

|---|---|

| 1 | pick the perfect welding twine: choose low-alloy welding wires which are specially designed for welding Corten steel to make certain ultimate consequences. |

| 2 | Preheat the material: Corten metal requires preheating earlier than welding to prevent cracking and make sure a robust bond among the materials. |

| 3 | Use the correct welding approach: hire proper welding strategies along with gradual travel speed and keeping a constant arc period to attain splendid welds. |

| 4 | protect the weld: protect the weld region from environmental elements consisting of moisture and contaminants to prevent corrosion and maintain the integrity of the weld. |

| five | publish-weld treatment: After welding, recollect making use of a weathering steel-unique primer to protect the weld and ensure its sturdiness. |

FAQs about Welding Corten Steel

What wire is used for welding Corten?

The ideal wire for welding Corten steel is a low-alloy welding wire with high tensile strength, good ductility, and corrosion resistance properties. These characteristics are essential for achieving strong, durable welds and maintaining the integrity of the material in outdoor environments.

Why is it important to select the right welding wire for Corten steel?

Choosing the right welding wire is crucial to ensure a successful welding process and achieve high-quality welds when working with Corten steel. Low-alloy welding wires are specifically designed to work well with Corten steel, providing corrosion resistance, strength, and compatibility with the material’s composition.

What are the key benefits of using low-alloy welding wires for welding Corten steel?

Using low-alloy welding wires offers several benefits, including corrosion resistance, strength, durability, compatibility with Corten steel, and maintaining the distinctive rust-like appearance of the material. These benefits contribute to the overall quality and longevity of the welded joints.

What are some tips for welding Corten steel effectively?

To weld Corten steel effectively, it is important to select the appropriate welding wire, preheat the material, use the correct welding technique, protect the weld from environmental factors, and consider post-weld treatment such as applying a weathering steel-specific primer to protect the weld and ensure its longevity.

What safety precautions should be taken when welding Corten steel?

When welding Corten steel, it is important to prioritize safety by using proper ventilation, wearing appropriate protective gear, keeping a fire extinguisher nearby, inspecting equipment, following proper welding techniques, and practicing good housekeeping to maintain a safe work environment.